OEM/ODM

Handbag,Luggage,Backpack design manufacturing

01

Initial Material Inspection

Material Quality Assessment: Conduct a meticulous inspection of incoming materials, including fabrics, zippers, and buckles, to check for quality, color consistency, and potential defects. This ensures only premium materials advance to production.

02

Design

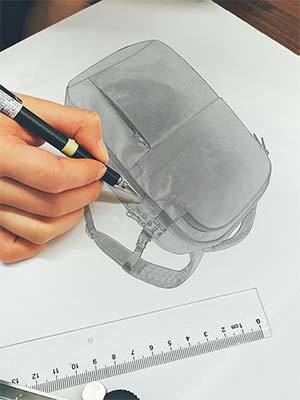

Concept Development: Utilize design software to create initial sketches and detailed bag designs, including style, dimensions, and features like pockets and straps. Digital Modeling: Develop 3D models and renderings to visualize the final product and make any necessary design adjustments before physical sampling.

03

Sampling & Proofing

Prototype Creation: Create sample bags based on design specifications, allowing designers to evaluate functionality, aesthetics, and construction quality. Testing & Feedback: Assess the prototype for design flaws or improvement areas and implement adjustments accordingly.

04

Pattern Making & Cutting

Pattern Development: Generate precise patterns for each component of the bag, which will guide fabric and material cutting. Material Cutting: Accurately cut materials according to patterns, ensuring all pieces align seamlessly for the assembly process.

05

Sewing & Assembly

Industrial Assembly Sewing: Stitch together cut pieces using industrial machines, adding elements like zippers, straps, and linings as specified. Quality Control: Regularly check stitching for consistency and strength, ensuring durability and adherence to quality standards.

06

Final Inspection

Quality Assurance: Conduct a comprehensive inspection of finished bags, reviewing stitching, construction, and overall appearance for any defects. Functionality Testing: Confirm that zippers, pockets, and straps function smoothly and meet design expectations.

07

Packing & Labeling

Protective Packaging: Secure each bag with protective materials (plastic bags, bubble wrap, or custom-designed boxes) to prevent damage during transit. Product Labeling: Attach labels and tags with product details, barcodes, and branding information.

08

Warehousing & Inventory Management

Organized Storage: Arrange packed bags systematically in the warehouse according to inventory protocols for efficient tracking and retrieval. Inventory Oversight: Maintain accurate records of stock levels and shipment movements to ensure optimal space utilization and streamlined inventory management.

Our Factory

Letong Backpacks started as a small traditional trading workshop and has grown into a full-fledged factory with over 80 dedicated employees.

Over the years, we have built a solid foundation in the bag manufacturing industry through steady development and hands-on experience.

To better manage labor, costs, and project specialization, we have set up satellite factories in Guangzhou, Shenzhen, and Huizhou, in addition to our main facility in Dongguan. Each location focuses on different product lines — for example, leather goods are typically produced in Guangzhou, luggage items in Huizhou, and backpacks are primarily handled in our Dongguan factory.

We are especially proud of our skilled team of pattern makers, many of whom have over 10 years of experience. Their expertise allows us to bring even the most challenging samples to life with precision and quality.

We understand you’re currently searching for the right supplier — don’t hesitate to reach out. I’m confident we can provide you with a solution that meets your expectations in both quality and execution.

What We Can Customize

These concise descriptions highlight the key aspects of our customization services.

Quality of Materials

- At Letong, we source only premium materials from trusted suppliers to ensure both durability and aesthetic excellence. Each material is rigorously tested for strength and sustainability, guaranteeing bags that stand the test of time in both form and function.

LOGO

-

We offer a range of advanced logo customization techniques, including silk screen printing, heat transfer, embroidery, and embossing. Our experienced team ensures precise logo placement and flawless execution, perfectly capturing and enhancing your brand's identity.

Size

-

Our bags are fully customizable in size, from compact toiletry bags to large travel backpacks. We tailor each bag's dimensions to meet your specific requirements, ensuring optimal functionality and user convenience.

Color

-

With a wide range of color options and custom dyeing capabilities, we can match your brand's exact color specifications. Our design experts work with you to select the ideal color combinations, enhancing each product's visual impact.